Depleted Fracture Identification

Parent-child well interactions can lead to compromised frac completions and significantly impact production. While there are several techniques for evaluating pressure communication between existing wells during or after fracturing treatments, greater value comes from the ability to identify and prevent or mitigate these fracture interactions.

Drill2Frac’s DFI is the only analysis method on the market that can precisely pin-point which areas of the lateral are most likely to cause fracture interactions, and provides the information necessary to mitigate them without sacrificing significant areas of the lateral. The DFI process identifies where infill wells cross existing fractures and predicts potential frac hits from new completions. DFI provides actionable recommendations using the same drilling data that creates our OmniLog® lateral profile. The process precisely locates conductive channels between wells by identifying areas of localized depletion. These areas are most often associated with fractures connected to a parent well.

Using the DFI process, operators can identify parent fractures in child wells, providing valuable insights for completion design.

- Identify/avoid/mitigate frac-hits

- Understand cluster efficiency

- Reduce completion costs

- Understand fracture growth that occurred in a parent well

- Provide insights into well spacing

“Drill2Frac was able to accurately map the depleted zones on a pad of child wells which

was later independently validated through monitoring of pressure response in the parent wells during fracturing.”

-Technology Manager – Appalachian Operator

Case Study

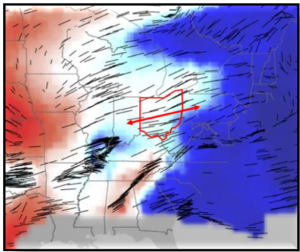

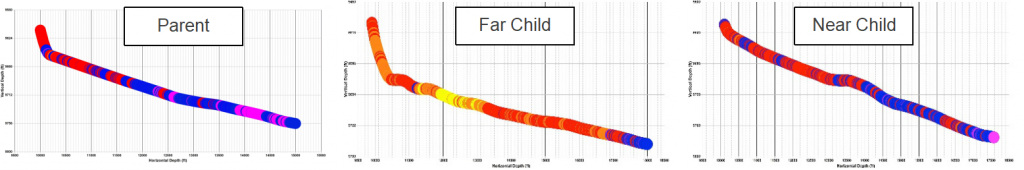

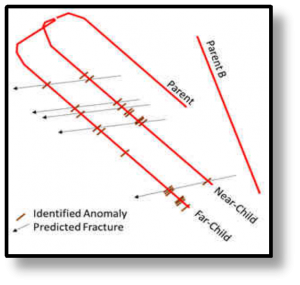

The DFI Methodology, was applied in the Point Pleasant (Utica) formation in Ohio. Two child wells were drilled next to a parent well that has been producing for greater than two-years.

Anomalies Identified

While no anomalies were identified in the parent well, multiple were identified in the child wells. Many of these anomalies were consistent across both child wells which is a strong indication that these are indeed fractures from the parent well.

Qualify Fractures

Fractures are qualified using a number of different approaches. For example, the azimuth of the fracture pairs not only is located across from the parent well, but also matches up with the local maximum stress direction.